Company Profile

Our company Shaanxi United Mechanical Co., Ltd. founded in July 2011. We have more than 100 employees. Including 5 senior engineers, 10 engineers 15 senior technicians and over 70 skillful operators for all kinds of machine tools. We have the registered capital of RMB 11 million. Our Manufacturing plant covers an area of 20,000 square meters

We have a professional team for technology research and development and dedicated team of technical workers in our UMC. We are very focused on scientific and technical talent.

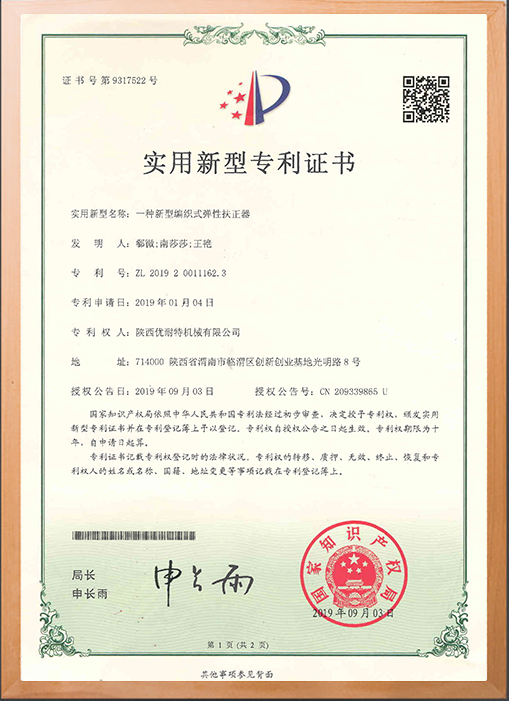

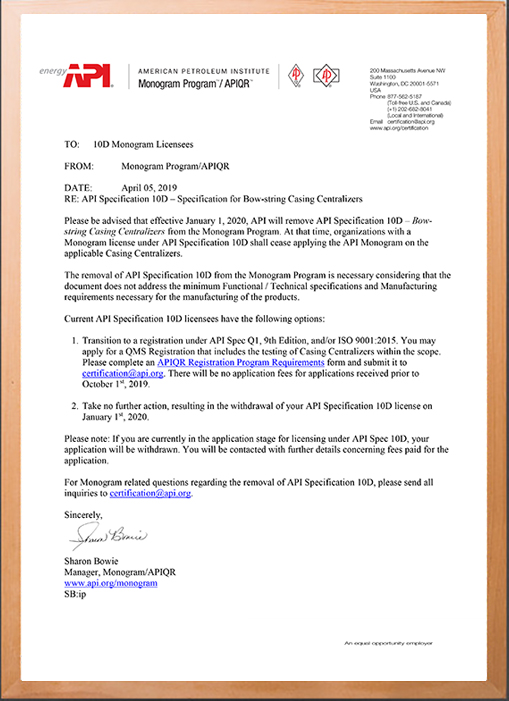

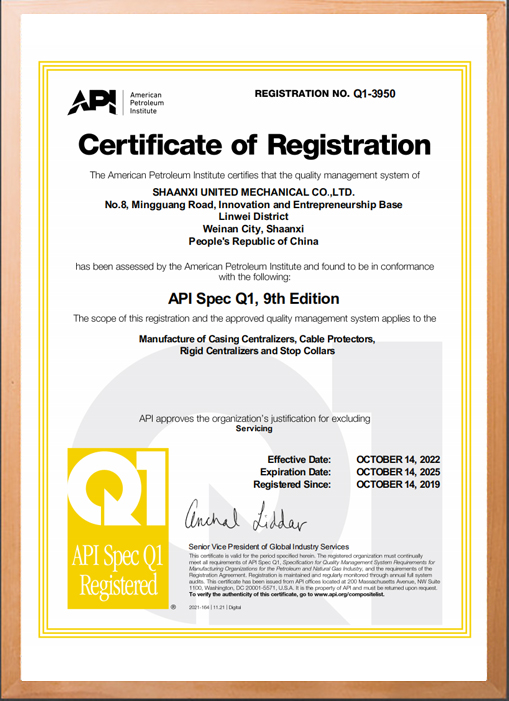

Company Honor

Shaanxi United Mechanical Co., Ltd has obtained ISO relative certificates .Such as the Quality Management System Certificate of ISO9001, the Environmental Management System Certificate of ISO14001, and Occupational Health and Safety Management System Certificate of ISO45001. And has acquired API certificate by the American Petroleum Institute certifies that the quality management system. Shaanxi United Mechanical Co., Ltd has its own variety types of patents of utility models certificates for centralizers and stop collars.

Company Culture

The objective of our company is to develop more, newer and more practical products with high quality for various enterprises in oil and other industry by our professional, dedicated, creative and efficient team.

The tenet of the company is sincere unity and innovation.

Company Culture

The objective of our company is to develop more, newer and more practical products with high quality for various enterprises in oil and other industry by our professional, dedicated, creative and efficient team.

The tenet of the company is sincere unity and innovation.

Enterprise Spirit

Our company advocates unity and innovation and excellent for quality and excellent service. Our belief that survival by quality and development by credit. Our company has a good corporate culture. Sincerity unity and innovation for product.

Product Advantage

Cable Protectors can help the oil industry with below aspects

1. Protect cables: Cables in the oil industry need to be moved and used frequently and are easily damaged. Cable protectors prevent cables from being frayed and damaged by friction, pressure, and other factors.

2. Increased safety: In the petroleum industry, cables are often used in dangerous environments. Installing a cable protector can reduce the occurrence of accidents and improve work safety.

3. Extend the life of the cable: The cable protector can provide extra protection and support for the cable, thus extending the service life of the cable. This reduces maintenance and replacement costs.

4. Improve efficiency: The production process in the oil industry requires many equipment and cables to be used together. If a cable is damaged or fails, it can lead to downtime and production interruptions. By installing cable protectors, this risk can be reduced and productivity can be increased.

Cable Protectors can help the oil industry with below aspects

1. Protect cables: Cables in the oil industry need to be moved and used frequently and are easily damaged. Cable protectors prevent cables from being frayed and damaged by friction, pressure, and other factors.

2. Increased safety: In the petroleum industry, cables are often used in dangerous environments. Installing a cable protector can reduce the occurrence of accidents and improve work safety.

3. Extend the life of the cable: The cable protector can provide extra protection and support for the cable, thus extending the service life of the cable. This reduces maintenance and replacement costs.

4. Improve efficiency: The production process in the oil industry requires many equipment and cables to be used together. If a cable is damaged or fails, it can lead to downtime and production interruptions. By installing cable protectors, this risk can be reduced and productivity can be increased.

What problem does the bow casing centralizer solve for the oil industry?

The bow casing centralizer is a kind of equipment used in the petroleum industry, which can be used to solve the deformation and bending of the casing in the well. These problems can arise during drilling, causing problems such as oil leakage from the wellhead. By using the bow-shaped casing centralizer, the casing can be restored to its original shape to ensure the safety and normal production in the well. At the same time, the bow-shaped casing centralizer can also improve drilling efficiency and reduce maintenance costs. It is one of the important equipment in the petroleum industry.

What problem does the bow casing centralizer solve for the oil industry?

The bow casing centralizer is a kind of equipment used in the petroleum industry, which can be used to solve the deformation and bending of the casing in the well. These problems can arise during drilling, causing problems such as oil leakage from the wellhead. By using the bow-shaped casing centralizer, the casing can be restored to its original shape to ensure the safety and normal production in the well. At the same time, the bow-shaped casing centralizer can also improve drilling efficiency and reduce maintenance costs. It is one of the important equipment in the petroleum industry.

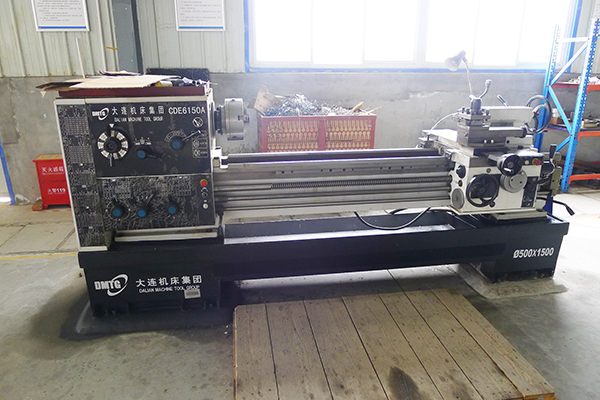

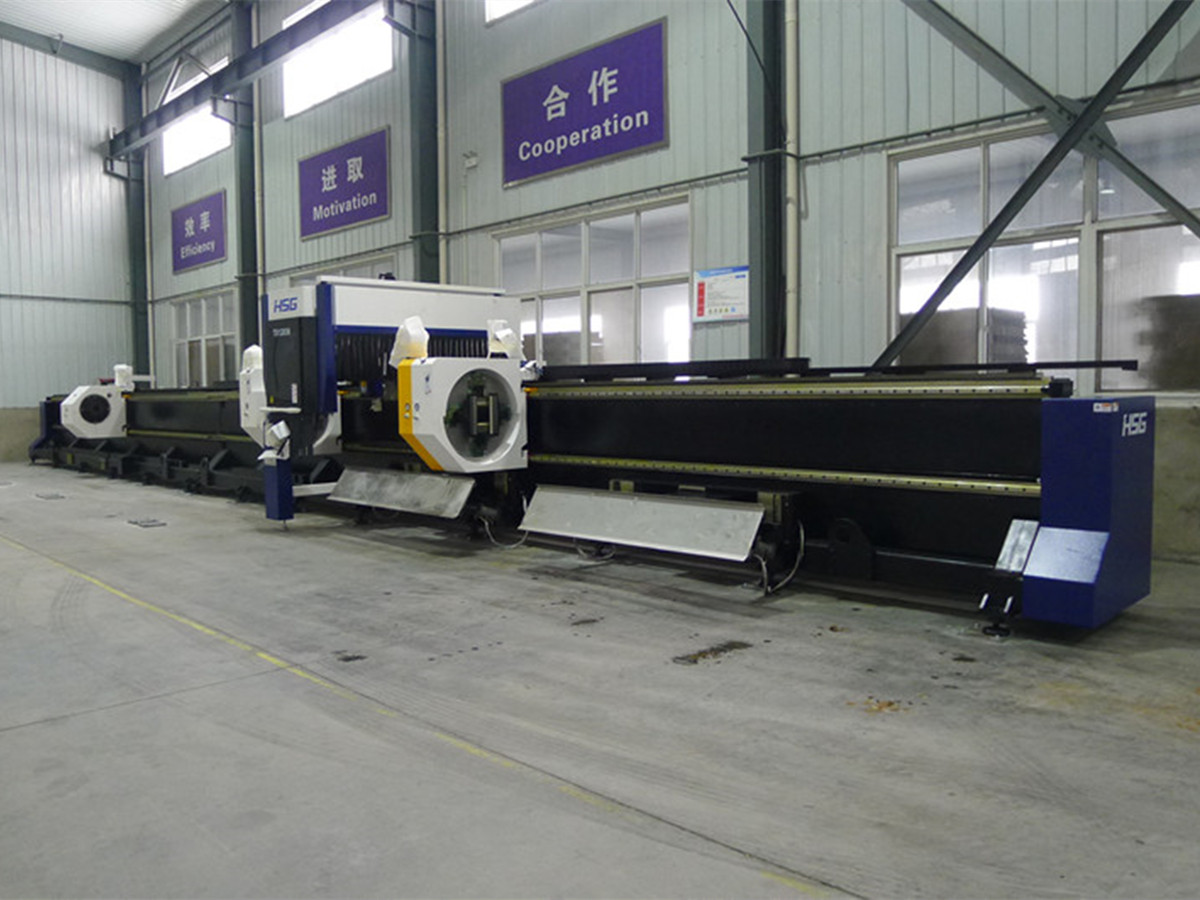

Equipment Introduction

Now the company has more than 100 equipment including 2 high-grade equipment which are one large-size NC laser cutting machine and one NC welding machine. It has one large plate shearer,one bending machine,more than 20 punch presses in different sizes, more than 10 ordinary machine tools and 6 large hydraulic presses. Also the company has 4 sets of heat treatment equipment and one production line of plastic spray and 2 sets shot blasting machine. With 5 sets of industrial robot welding equipment. High-grade equipment and scientific combination of human and machines ensure the high standard and best quality of the products.

Manufacturing Plant Environment

The environment of plant is very clean and tidy. Everyone works in our plant should wear the mask and wear the work uniform and ear plugs and must wear protective work shoes.

And for the special area, The workers must wear the protective glasses and mask. such as the polishing area of workers must wear the protective glasses and mask.

The spray treatment area of workers must wear the dust mask and glasses.

The welding area of workers must wear the weld cap and glove.

The laser cutting area of workers must wear the protective glasses.

All the women who worked in the work shop must have their hair tied up and wearing the work cap.

Generally, we have the safety instructions to each worker when they will be come to the plant. Also there are safety slogan in our manufacturing plant.

There is a person responsible for each production line. And there are rules and regulations in our company. Employees of the company will consciously abide by the rules and regulations.

Everyone would work hard in our company under the leadership of our general manager Mr. Zhang.

Packaging & Transportation