In oil drilling operations, every tool and piece of equipment plays a vital role in ensuring a smooth and efficient process. One such tool is the bow spring casing centralizer, which is specially designed to improve the quality of cementing during drilling.

Bow spring casing centralizers are known for their superior resilience and wear resistance. This unique combination ensures that it can withstand harsh drilling environments and significantly extend its service life. This tool becomes especially important when drilling in challenging conditions, as it can withstand intense pressure and wear without losing its effectiveness. Unlike other centralizers, bow spring casing centralizers allow oil drilling companies to achieve superior cementing results.

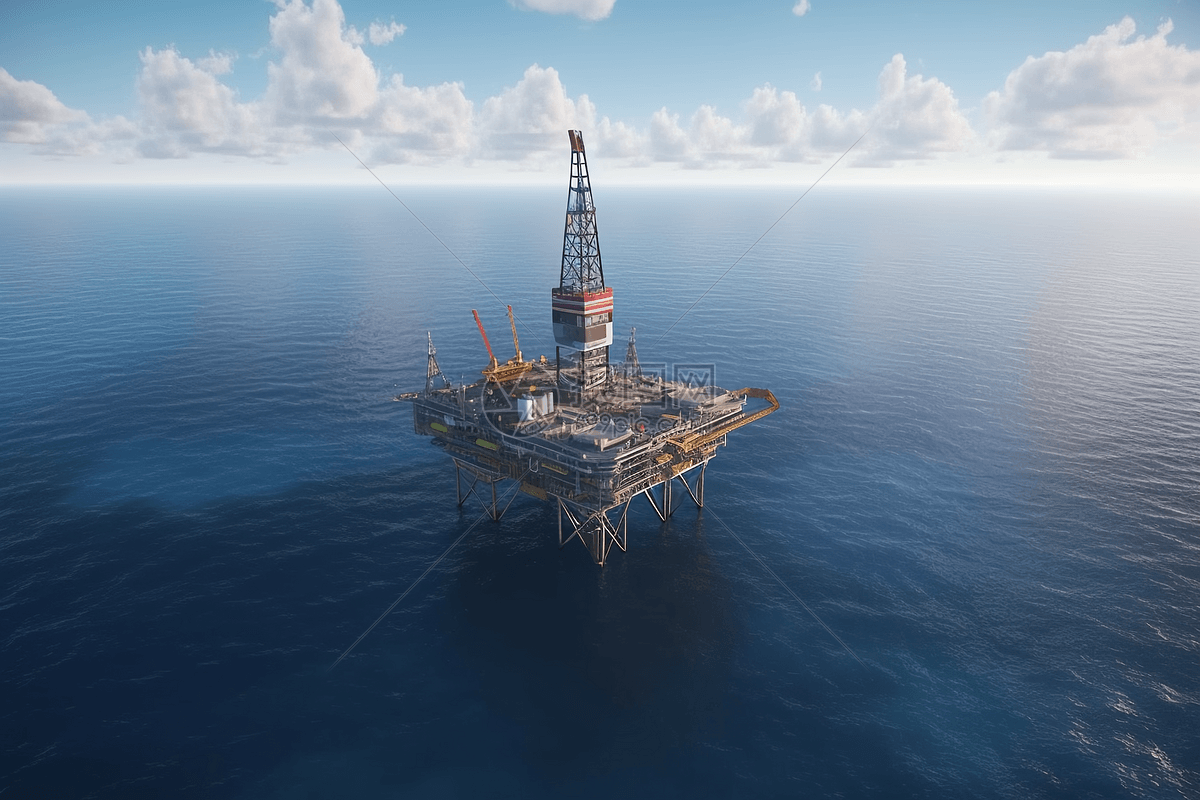

In addition, this centralizer is suitable for various well types and diameters, making it versatile and widely used in the industry. Whether drilling shallow or deep wells, onshore or offshore, the tool can accommodate different environments and casing sizes. Bow spring casing centralizers have complete specifications and can meet the diverse requirements of drilling operations.

Additionally, bow spring casing centralizers offer the added advantage of customization. With the ability to design to customer specifications, drilling companies can customize centralizers to their specific needs. This customization ensures that the centralizer is perfectly suited to the unique challenges and goals of the drilling operation, increasing its efficiency and effectiveness.

What’s more, during the cementing process, the bow spring casing centralizer plays a vital role in the centering of the casing. Utilizing the support of the bow, the tool ensures that the casing remains in proper alignment, preventing any misalignment that could affect the quality of the cement. By keeping the casing perfectly centered, centralizers allow for a more even and consistent cement application, improving overall cement quality.

Web: https://www.sxunited-cn.com/

Email: zhang@united-mech.net /alice@united-mech.net

Phone: +86 136 0913 0651/ 188 4043 1050

Post time: Jul-26-2023